COMOS

Systém pro správu a údržbu technologických celků

Společnost VDT Technology a.s. nabízí systém pro řízení celého životního cyklu technologického celku.

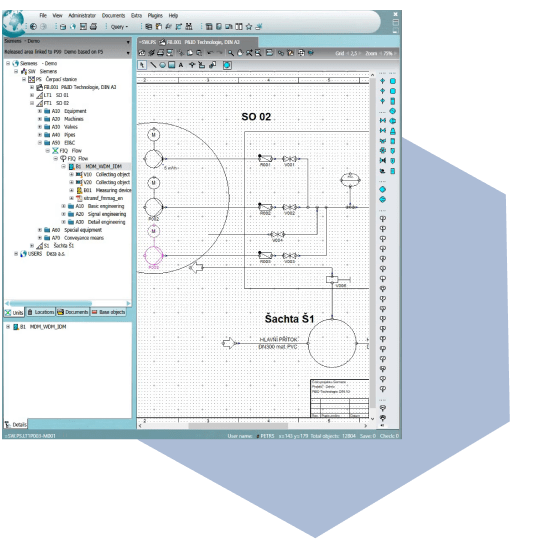

Vzhled

VÝHODY

Objektová architektura

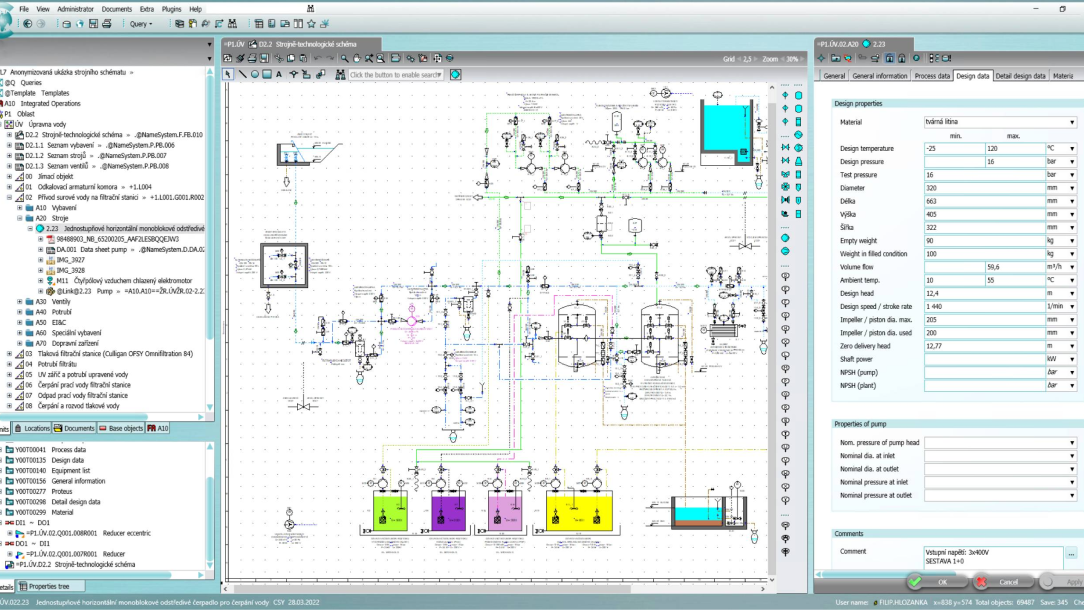

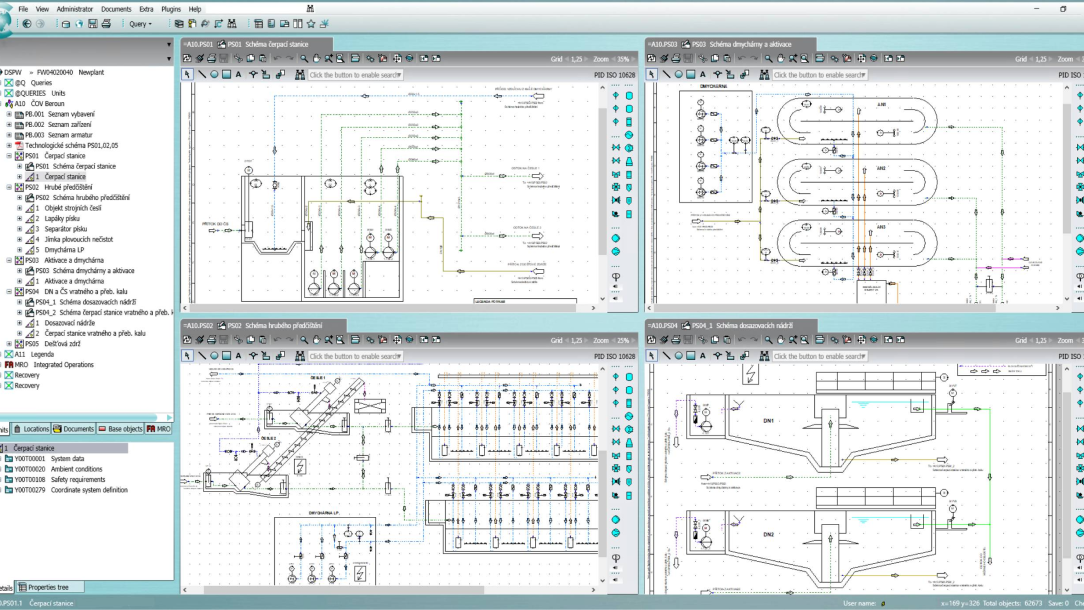

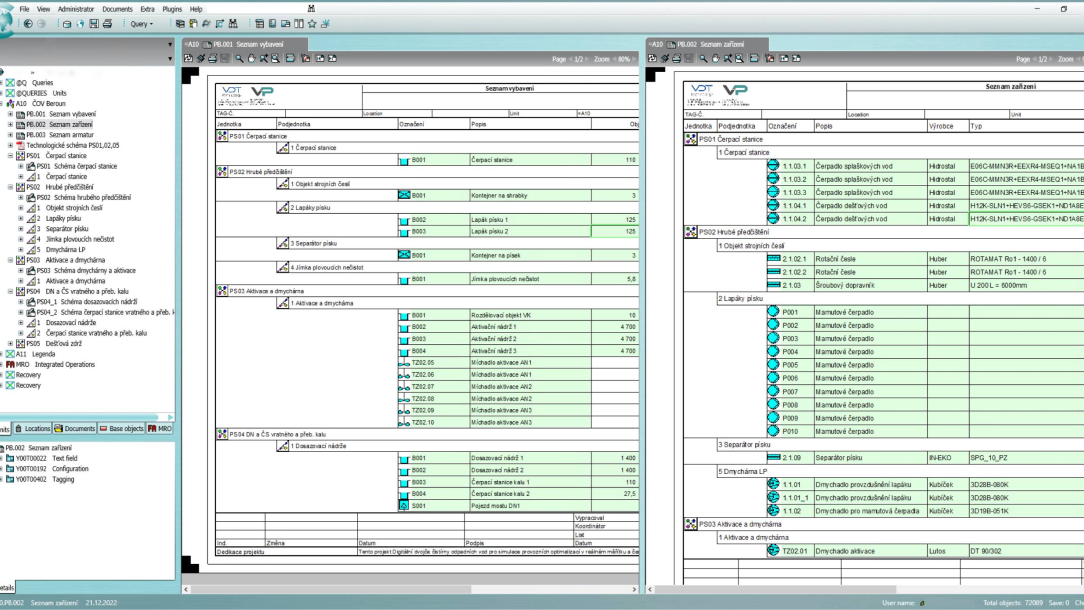

Díky využití objektové architektury pro správu informací o veškerých součástech technologického celku je zaručena správnost informací napříč všemi profesemi. Změny provedené na objektu se automaticky aktualizují do veškerých jeho výskytů, schémat a technických listů. Systém díky tomu také sám dokáže kontrolovat správnost zadaných informací, jako jsou například průtoky skrz všechny objekty na jednom rameni potrubí nebo směry zapojení jednotlivých technologií.Objekty umožňují rozsáhlou interaktivitu práce s dokumentací. Automatické generování technických listů, seznamů zařízení nebo reportů je otázka pár kliknutí.

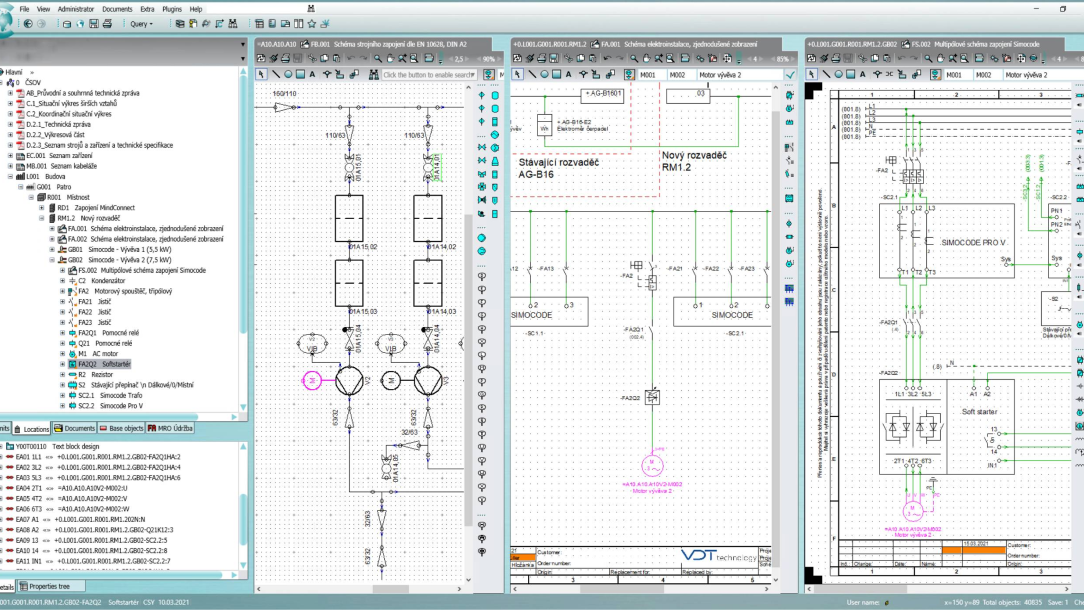

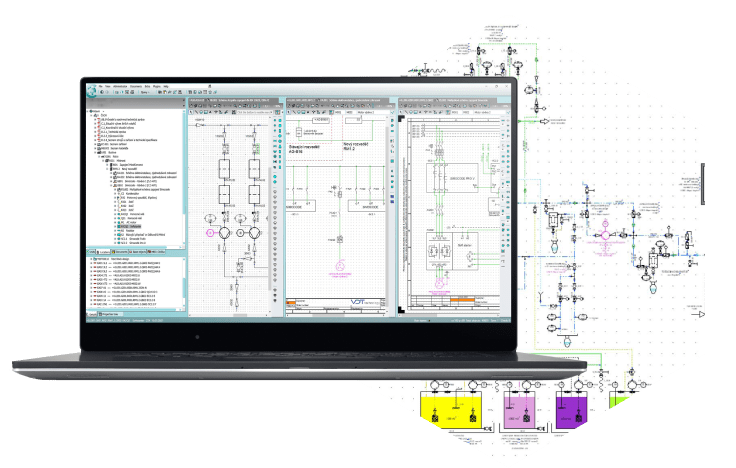

Propojenost profesí

V systému COMOS je možné tvořit dokumentaci strojní, jednopólová i více pólová schémata, smyčkové diagramy řízení nebo i návrhy vstupů a výstupů PLC počítačů, které je možné importovat do řídících systémů. Všechny profese jsou v systému navzájem propojené, takže je možné se z objektu na strojním schématu přesunout na jeho výskyt na schématu elektroinstalace pomocí jednoho kliknutí.

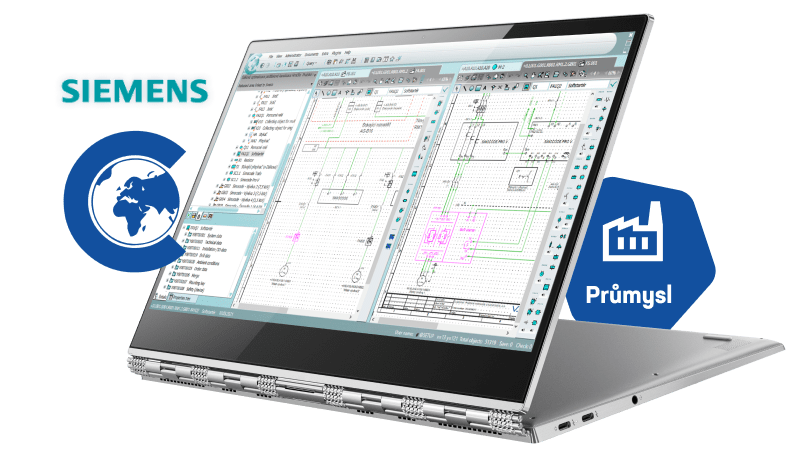

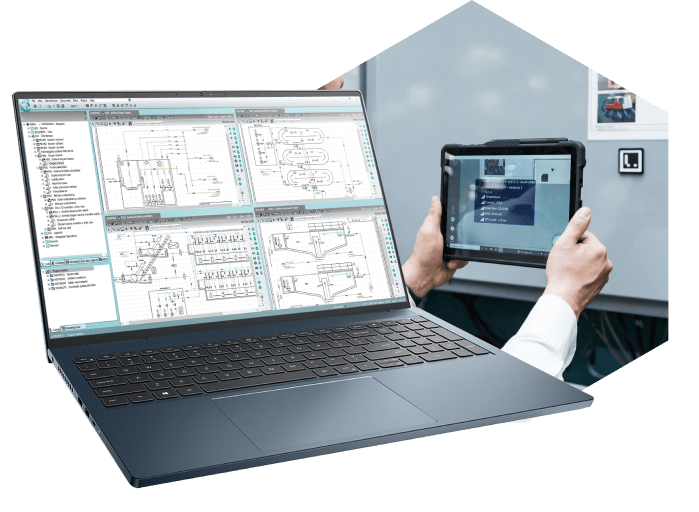

Webové prostředí - COMOS web

Celý systém se všemi informacemi je dostupný přes webové rozhraní, případně se k němu dá přistupovat přes mobilní aplikaci COMOS Mobile Worker. Údržba si tak může vzít s sebou všechny informace o provozu přímo na místo v tabletu nebo telefonu a rovnou vyplnit provedené údržbové úkony, případně je i doplnit o fotodokumentaci.

Webové prostředí - COMOS web

Celý systém se všemi informacemi je dostupný přes webové rozhraní, případně se k němu dá přistupovat přes mobilní aplikaci COMOS Mobile Worker. Údržba si tak může vzít s sebou všechny informace o provozu přímo na místo v tabletu nebo telefonu a rovnou vyplnit provedené údržbové úkony, případně je i doplnit o fotodokumentaci.

Přínosy využití systému COMOS

Zkrácení údržbových úkonů

Zkrácení údržbových úkonů Lepší přehlednost a kvalita dokumentace

Lepší přehlednost a kvalita dokumentace Snížení nákladů na údržbu a provoz

Snížení nákladů na údržbu a provoz Zaručení jednotnosti a integrity dat

Zaručení jednotnosti a integrity dat Preventivní údržba díky dynamickým datům

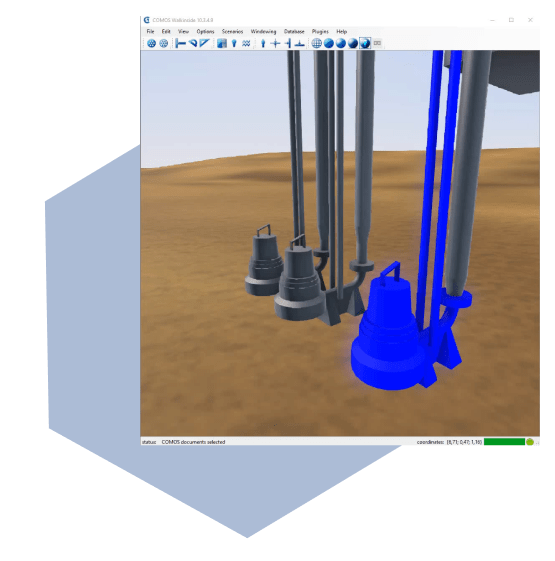

Preventivní údržba díky dynamickým datůmCOMOS Walkinside

- •3D zobrazení celého technologického celku

- •přímé propojení s databází

- •vytvoření digitálního dvojčete pro možnost simulace změn

COMOS Mobile Operations

- •přístup přes webové rozhraní ke kompletní databázi z jakéhokoliv zařízení

- •možnost zálohování databáze pro práci v offline režimu

COMOS Mobile Worker

Reference - Česká republika

Reference - zahraničí

Zaujal Vás náš produkt