APPLICATION

New Plant

Digital Twin of a Wastewater Treatment Plant

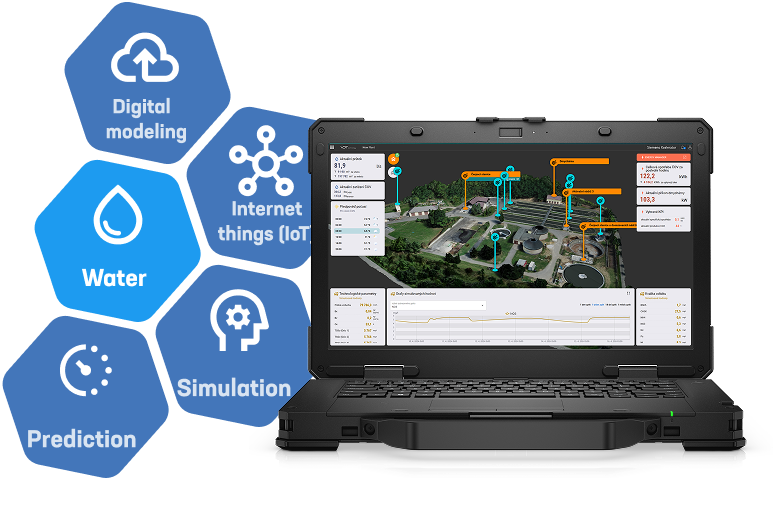

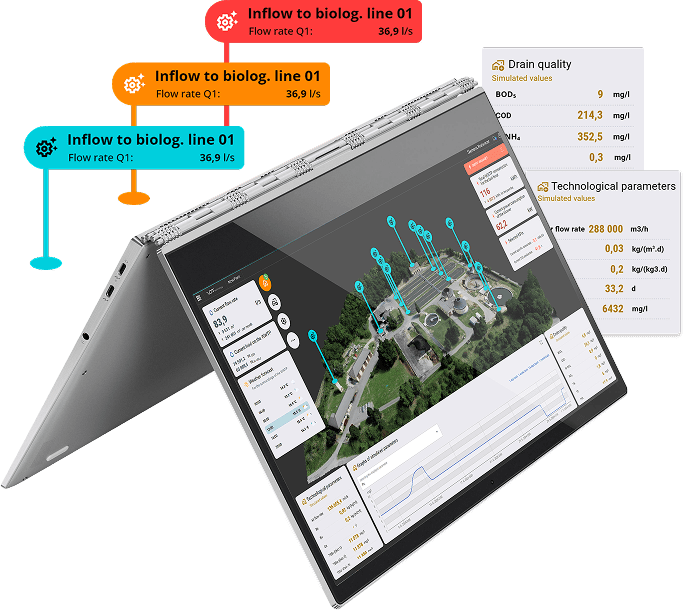

The application monitors and displays key values of wastewater treatment plants through a digital twin of the water management facility, which is connected to real-time data from the operation and continuously updated.

The primary function of the application is the mathematical modeling of processes in the wastewater treatment plant.The ability to simulate processes allows for optimizing the treatment plant’s operation and reducing its operational costs.

Application

Appearance

APPLICATION New Plant

Features

Real-Time Monitoring

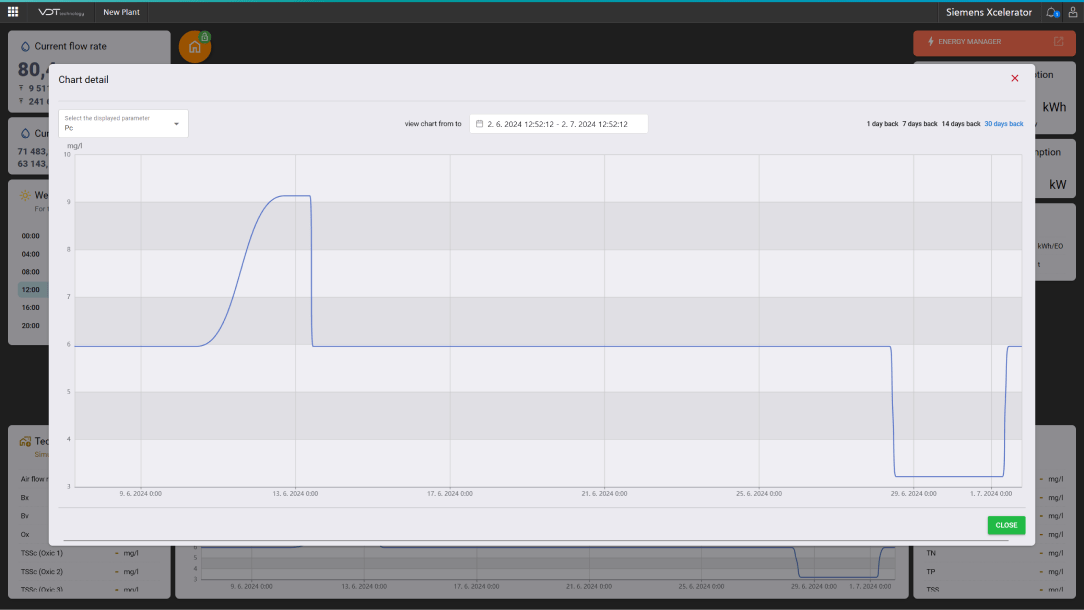

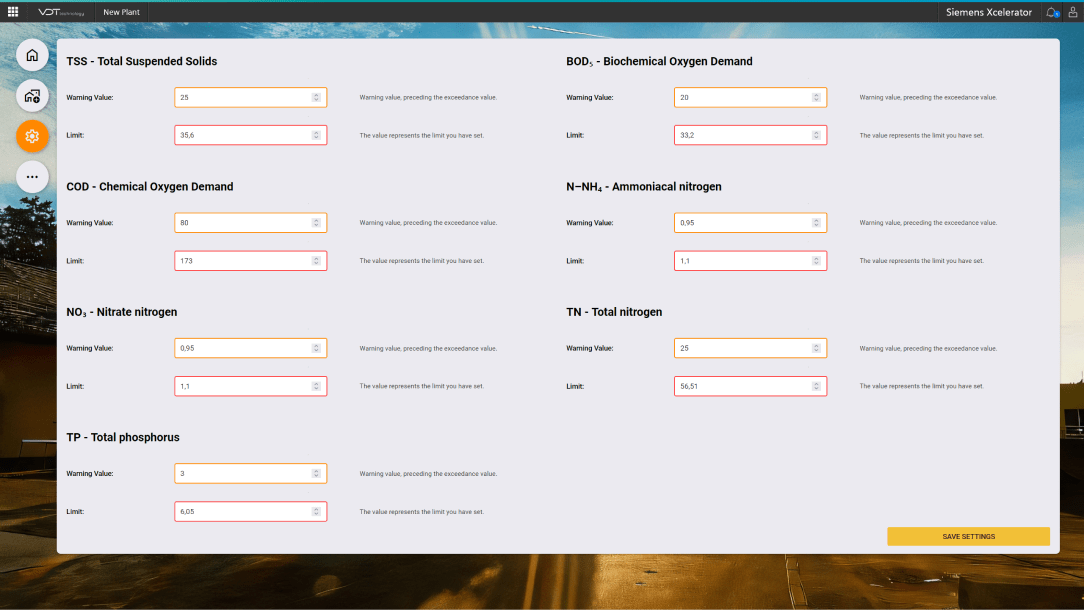

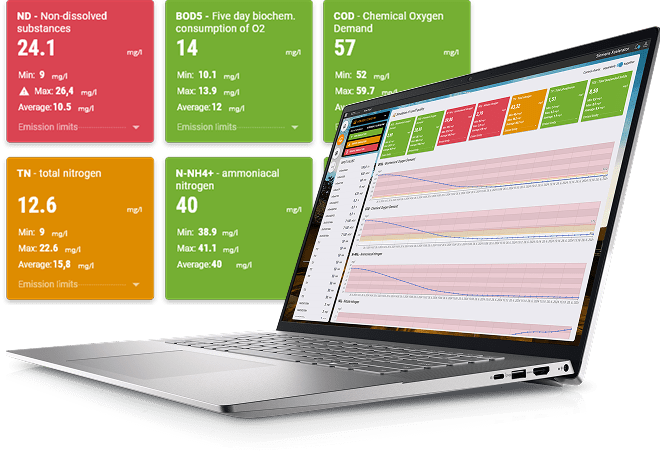

Modern technology enables wastewater treatment plant operators to gain precise and detailed insights into the current state and operation of the facility. A virtual 3D model, connected with real-time data directly from operations, provides users with a visually clear view of individual equipment sections.Online operation simulations with a 24-hour forecast also allow operators to plan and prepare for potential fluctuations, particularly in terms of material load at the outflow. Additionally, graphs of measured values with access to historical data are available, supporting trend analysis, problem identification, and process optimization.

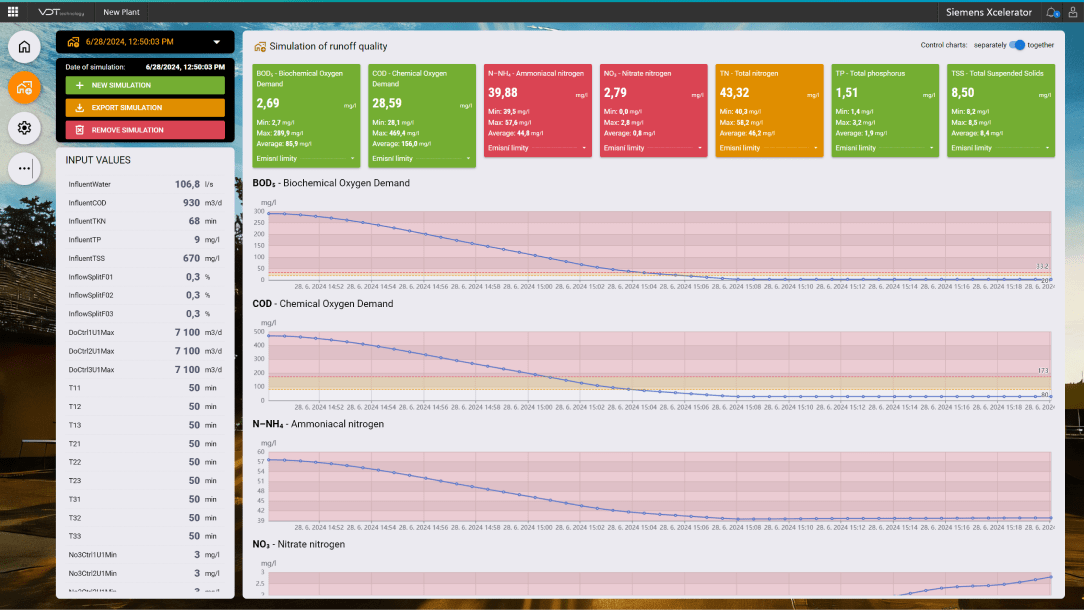

Simulation

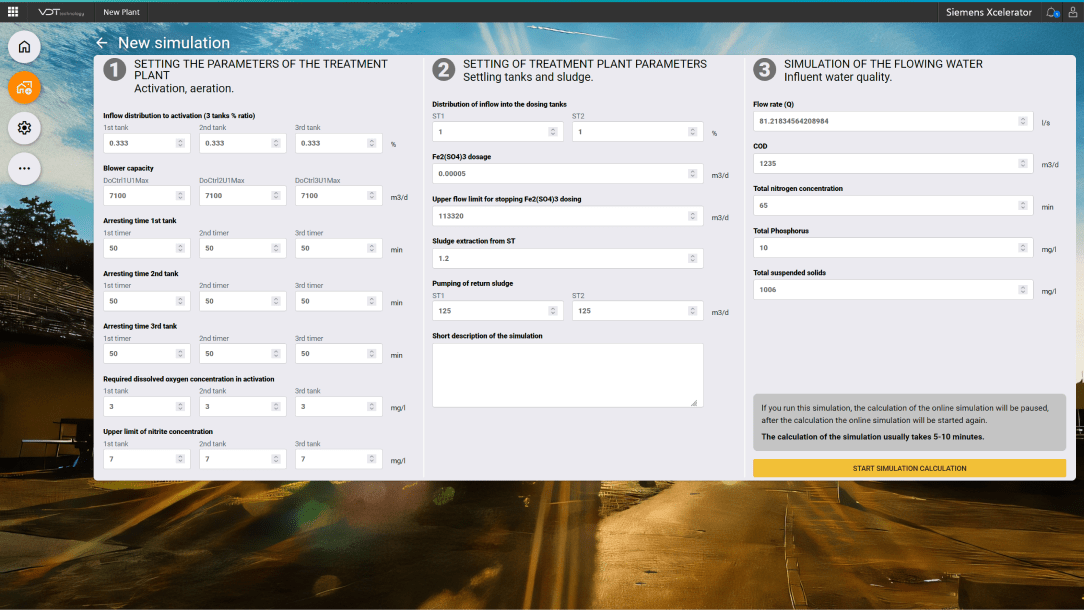

Simulations are a key feature of the application, allowing detailed analyses based on mathematical models and any input data. This functionality enables users to precisely track how various factors impact the operation and efficiency of the treatment plant.The application offers two types of simulations:- •Online Simulations: These run continuously and utilize real-time operational data to simulate material load at the outflow of the treatment plant. This provides operators with the information needed for quick and accurate decision-making.

- •Custom Simulations: These simulations allow users to input their own or current operational data, creating opportunities for detailed analysis of plant behavior, including monitoring energy balances and optimizing individual processes.

This functionality significantly contributes to more efficient operation management and planning.

Additional Benefits of the New Plant Application

- •A user-friendly interface.

- •Detailed insights into the expected cleaning process and its efficiency.

- •Output parameters: NL – suspended solids, BSK5 – five-day biochemical oxygen demand, CHSK – chemical oxygen demand, Nc – total nitrogen, N-NH4+ – ammoniacal nitrogen, Pc – total phosphorus.

- •Ability to simulate various operational states and examine plant behavior under different operating modes.

- •Integration with En-Key application, which allows users to monitor energy consumption across various devices, analyze, and optimize energy usage to reduce costs and improve energy efficiency.

- •Integration with COMOS software, which enables the creation of all types of technical documentation, including PLC computer control logic.

HOW TO CONTACT US

Interested in our product

AREA OF INQUIRYSales and Implementation

T+420 277 004 040