COMOS

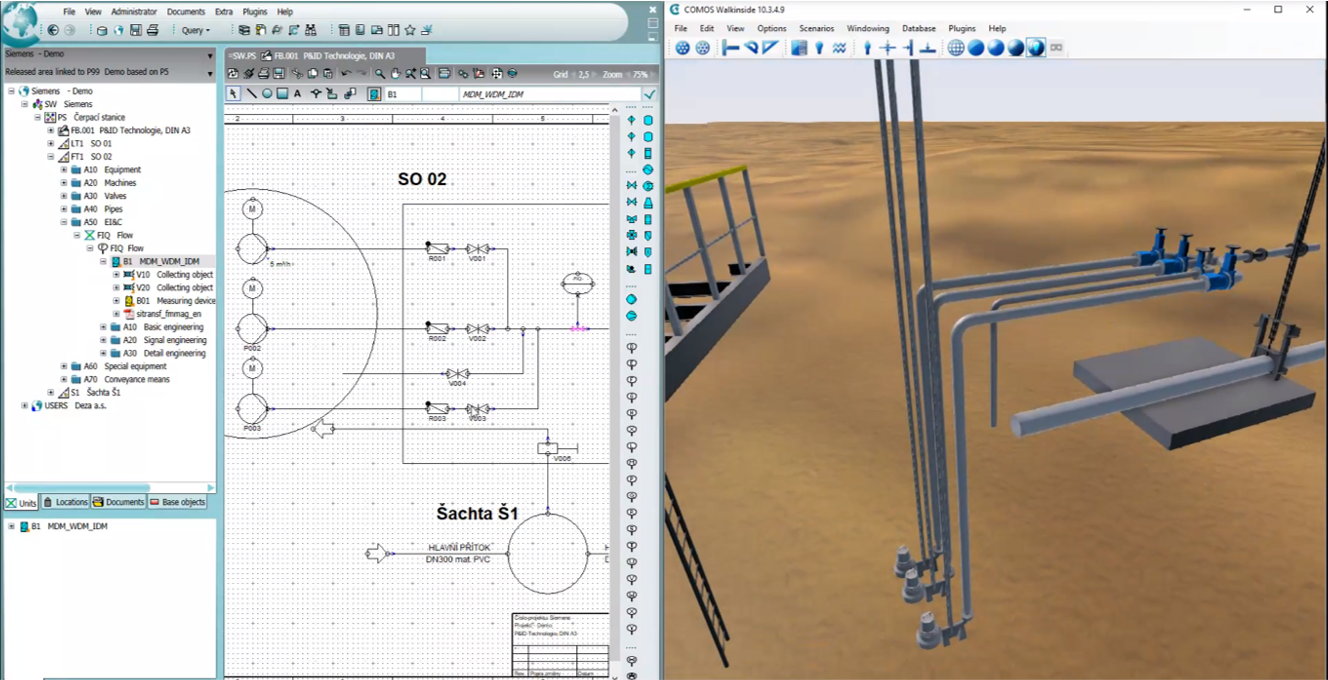

System for management and maintenance of technological units

COMOS

VDT Technology a.s. offers a system for the management of the entire life cycle of a technological unit.

From design through design in all stages, streamlining work with new and existing documentation to maintenance, all within one user environment.

Object architecture

By using object architecture to manage information about all components of a technological unit, the correctness of information across all professions is guaranteed. Changes made to an object are automatically updated to all its occurrences, schematics and datasheets. The system is also able to check the correctness of the information entered, such as the flow rates through all objects on a single pipe leg or the connection directions of individual technologies.

The objects allow for extensive interactivity when working with the documentation. Automatic generation of technical sheets, equipment lists or reports is a matter of a few clicks.

Connectivity of professions

In COMOS it is possible to create machine documentation, single and multi-pole schematics, control loop diagrams or even designs for PLC computer inputs and outputs that can be imported into control systems. All professions are interconnected in the system, so it is possible to move from an object on a machine diagram to its appearance on a wiring diagram with a single click.

Web environment

The entire system with all information is available via a web interface or can be accessed via the COMOS Mobile Worker mobile app. The maintenance staff can take all the information about the operation directly to the site on their tablet or phone and directly fill in the maintenance tasks carried out or even add photo documentation.

Integration

COMOS supports cooperation with many complementary systems. It is possible to import and export to standard Microsoft Office formats, generate PDF documents for printing, link to inventory in SAP, or link to 3D models in E3D and AVEVA PDMS. For any other solutions, data connection via REST API or data exchange via XML files is possible.

Consequences of using COMOS

Better clarity and quality of documentation

Better clarity

and quality of documentation

Reduced maintenance

and operating costs

Quaranteeing data

uniformity and integrity

Preventive maintenance thanks to dynamic data

COMOS Mobile Worker

- mobile application for maximum efficient maintenance

COMOS Web

- preview of mobile application for maximum efficient maintenance

Reference

Gas Storage CZ (ČEPS), ČEZ PPE Počerady

- Dokumentace vedená v systému COMOS

Pražská vodohospodářská společnost,

Úpravna vody Železná Ruda, ČOV Beroun

- Pilotní projekty digitálního dvojčete využívající COMOS

Doosan Škoda Power, Casale Project

- Automatické generování technické dokumentace

- Zefektivnění inženýrských prací o 30 %

Škoda Auto Kvasiny, Nexen Tire Žatec

Evidence údržby výrobních linek